We can deliver projects on a full turnkey basis, directly to end users, or work as an intergral part of the main contractor's team.

Norwood’s doors are always open to our customers and we welcome your input and ideas for project designs. We house a sample room displaying prototypes which can be manufactured and presented on request. This provides an opportunity to view, touch and feel the product, offering a more hands-on approach which sets us apart from other suppliers within the industry.

We encourage clients to engage with Norwood at an early design stage, in order to quickly grasp the project’s needs and offer the most suitable products. Adopting a proactive and flexible approach to design, we can incorporate power, data, security, fire protection and utilities into every partition, combining functionality with an anaesthetic appeal. Operating in highly regulated industries, we pride ourselves on our strong attention to detail, and we provide integrated compliant designs, underpinned by high-quality BIM Revit families.

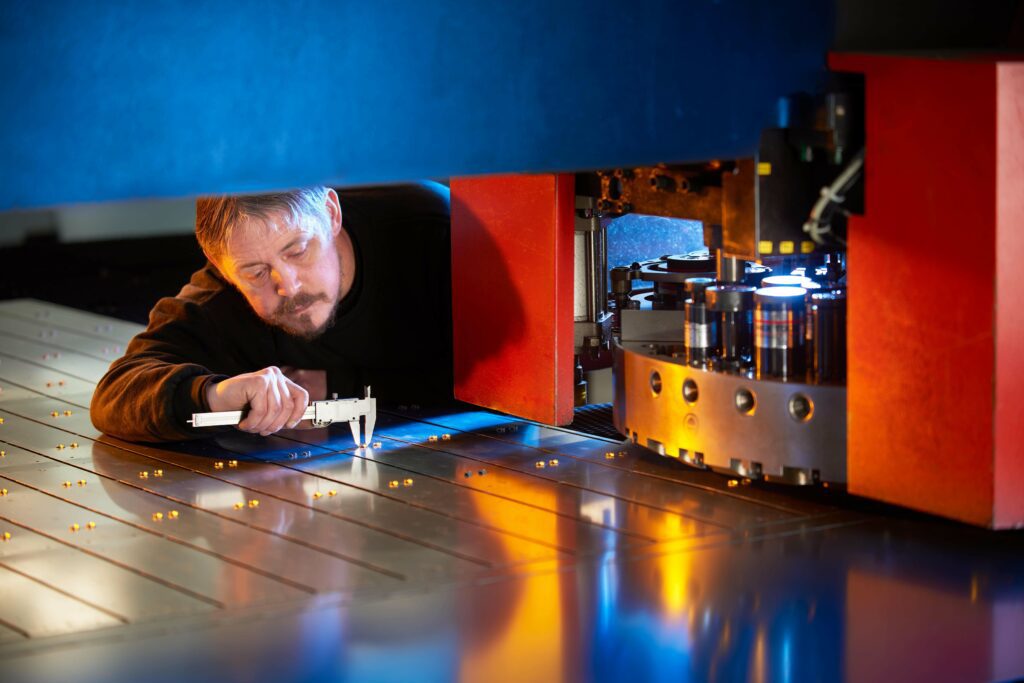

Utilising the latest technology, we manufacture all our products, including steel and glazed partitions, ceilings, and doors, in our factory in Stockport, UK. Our state-of -the art equipment and manufacturing systems allow us to run 24-hour production to ensure that we can meet the most challenging deadlines. We offer steadfast quality through careful selection of only the most robust and reliable materials.

The system offers a high degree of off-site construction which guarantees a high-quality finish to consistent tolerances, whilst offering the customer an accelerated programme. Our highly qualified site team strives to reduce risk, ensuring that all site activities are executed safely, protecting our employees and partners.